Features

- Top technology with national patent

- Customized design and reasonable price.

- Non-dust workshop with experienced engineers.

- Main machines adopt Siemens motor and imported SKF/NSK bearing.

- PLC control(Siemens) and Schneider or Soft Starter electric control system.

- Long service time and stable operation.

- Guide installation and commissioning is available.

Technical Parameters

- Capacity: 0.5t/h-30t/h or even more

- Dimensions: Designed according to specific requirements

- Power consumption: would be listed in the quotation,

actual consumption is 20-30% lower than theory.

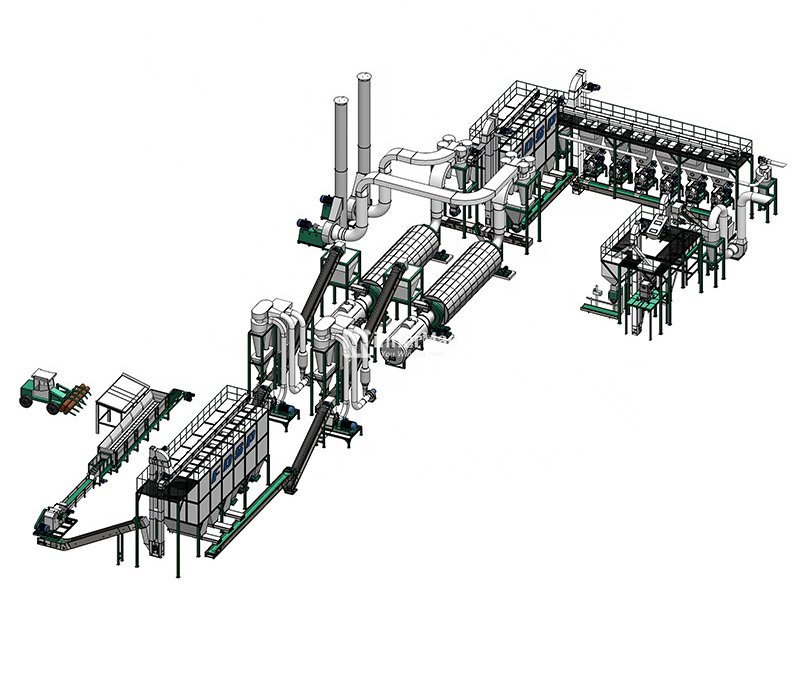

Pellet production line process:

(a)Peeling Process Wood debarker machine is applicable to peel the log of MDF board and papermaking industry, it is mainly used to peel log, small wood and so on, the peeled rate is more than 95 percent.

(b)Chipping Process

In the pellet plant before raw materials are made into biomass pellets, they are first reduced into much smaller, uniformly-sized particles. When the thicknedd is larger than 10mm or the size is greater than 50*50mm, a chippper is needed to chip these materials into smaller pieces.

(c)Grinding Process

The hammer mill is used to further crush these small pieces into particles of less than 3mm in diameter.

(d)Drying Process

After raw materials are crushed a dryer is needed since most raw wood materials have a moisture content of about 50%. However, the optimal moisture content for pelletiztion is 13%-15%. Therefore a rotary dryer is included in the pellet plant to reduce the moisture content. After crushing and drying you can begin making wood pellets.

(e)Pelletizing Process

After crushing and drying the raw material properly it is then ready for the pellet mill. The pelletizing machine or press is the key piece of machinery in the pellet plant. It should be mentioned that impurities in the raw materials like metal or stone,may damage the die and rollers of pellet making machine.

(f)Cooling Process Usually after pelletizing, the temperature of pellets is between 60-80 degrees and the moisture content is close to 15%. For storage purpose, a cooler must be used to reduce their surface temperature and moisture content.

(g)Packing Process Finally is the packing process. In order to protect the wood pellets becoming getting damp and to increase storability, proper packing is necessary.

Our Services:

- 24 Hours Online Service.

- Inquiry will be replied within 2 hours.

- All-the-way tracking service offered from placing order to delivery.

- Professional guide installation.

- One year warranty and all-round after-sales service.

- Customized design and flow chart.

- Independent R&D team and strict & scientific management system.

Ruminant Feed Pe

Ruminant Feed Pe livestock feed p

livestock feed p 1-30TPH poultry

1-30TPH poultry  cheap price and

cheap price and  Horizontal Mixer

Horizontal Mixer Hammer Mill,Whea

Hammer Mill,Whea Straw hammer mil

Straw hammer mil Alfalfa Feed Pe

Alfalfa Feed Pe